The Science Behind Effective Transformer Oil Regeneration Plants

The Science Behind Effective Transformer Oil Regeneration Plants

Blog Article

Cost-efficient and Eco-Friendly Transformer Maintenance With Regenerated Oil

The assimilation of restored oil in transformer upkeep presents a compelling technique for organizations seeking to improve both cost-efficiency and eco-friendliness. By using oil that keeps efficiency criteria akin to virgin alternatives, companies can dramatically reduce operational prices while simultaneously reducing their environmental effect.

Understanding Regenerated Oil

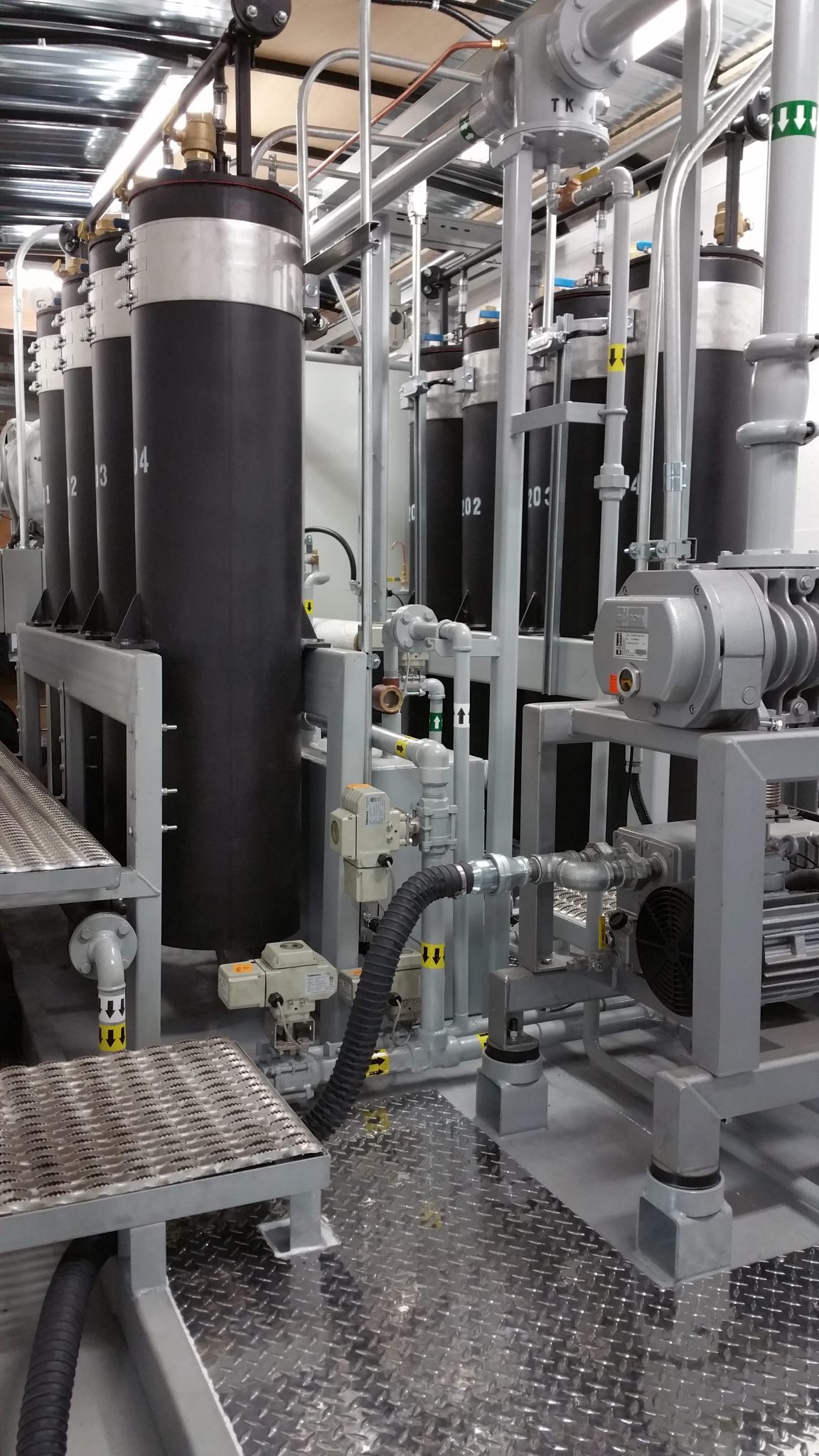

Regrowed oil, typically described as re-refined oil, is a critical component in the maintenance of transformers, providing both environmental and economic advantages. This oil is stemmed from made use of mineral oils that have gone through an extensive purification process, efficiently removing contaminants and restoring the oil to a top quality equivalent to virgin oil. The regrowth procedure typically involves numerous phases, consisting of physical separation, chemical treatment, and filtration, ensuring that contaminations such as sludge, water, and hefty metals are eliminated.

The utilization of regenerated oil in transformers is essential for maximizing efficiency and prolonging equipment life-span. High-grade re-refined oil keeps its dielectric buildings, making sure efficient insulation and avoiding electric malfunctions. Additionally, it has exceptional thermal conductivity, which helps in taking care of the functional temperatures of transformers, inevitably boosting their dependability and efficiency.

In addition, embracing regenerated oil not just supports economical maintenance methods but additionally reduces the requirement for new oil production, thereby saving natural deposits. Transitioning to re-refined oil is a smart choice for companies aiming to preserve high functional standards while concurrently managing budget restraints. Understanding the buildings and advantages of regrowed oil is crucial for notified decision-making in transformer maintenance techniques.

Ecological Benefits

The usage of restored oil in transformer maintenance uses substantial environmental benefits that add to lasting methods within the energy field. One of the main advantages is the decrease of waste oil disposal, as regenerated oil is stemmed from the recycling of utilized transformer oil, dramatically decreasing the quantity of harmful waste generated. This procedure assists alleviate the ecological threats connected with inappropriate disposal techniques, which can lead to dirt and water contamination.

Additionally, the regeneration procedure saves natural deposits by decreasing the requirement for brand-new base oil production - Reclaimed Transformer Oil. This conservation initiative not just reduces the removal influence on environments yet additionally decreases the carbon impact linked with oil production. By embracing restored oil, firms can enhance their dedication to environmental stewardship and line up with global sustainability goals

Moreover, using regenerated oil boosts the general effectiveness of transformers, resulting in decreased energy losses and lower greenhouse gas exhausts. As the power industry progressively faces stress to lessen its environmental influence, accepting regrowed oil represents an aggressive strategy to accomplishing both functional and environmental objectives. In recap, the environmental benefits of making use of regenerated oil are diverse, promoting a much healthier world while supporting the power market's change in the direction of sustainability.

Expense Cost Savings and Efficiency

Making use of regenerated oil in transformer upkeep can lead to substantial cost financial savings and enhanced functional effectiveness for energy business. Restored oil, created through innovative purification procedures, offers equivalent performance to brand-new oil at a fraction of the expense. By recycling oil that would or else be discarded, business can reduce their investing in costs while decreasing waste disposal prices.

Furthermore, the long term life cycle of regenerated oil translates to minimized regularity of oil modifications, causing lower labor expenses and lowered downtime for maintenance activities. Transformer Oil Regeneration Process. This not just enhances operational efficiency yet additionally enables a much more streamlined upkeep schedule, enabling companies to assign sources much more efficiently

Furthermore, making use of regenerated oil can cause lower insurance policy costs due to its ecologically friendly account. As power firms encounter increasing scrutiny regarding their ecological impact, adopting sustainable practices such as using regrowed oil can boost their online reputation and possibly bring in financial investment.

Inevitably, the assimilation of regenerated oil into transformer maintenance practices presents a tactical chance for energy companies to achieve substantial cost savings while advertising functional effectiveness, thereby lining up monetary performance with environmental responsibility.

Contrast With Standard Oils

While traditional oils have long been the criterion in transformer upkeep, a detailed contrast exposes that important site regenerated oils provide several benefits that boost performance and sustainability. Conventional mineral oils, while effective, often present environmental risks, directory such as contamination and disposal concerns. In comparison, regenerated oils are obtained from recycled materials, significantly lowering their eco-friendly footprint.

Among the crucial differentiators is the chemical stability of regenerated oils. They typically show remarkable oxidative stability, which converts to longer life span and reduced regularity of oil modifications. This particular not only enhances transformer efficiency but also minimizes downtime and upkeep costs. Furthermore, regenerated oils frequently have lower degrees of damaging additives, making them a much safer choice for the environment and both devices.

In addition, regenerated oils offer exceptional dielectric buildings, guaranteeing reliable electric insulation. This quality is vital in keeping transformer functionality under varying functional problems. The use of regenerated oils likewise lines up with international sustainability goals, interesting organizations dedicated to lowering their carbon impact. Overall, the advantages of regenerated oils over traditional oils highlight their prospective to change transformer upkeep practices, providing a much more reliable and liable alternative.

Implementation in Maintenance Practices

When the assessment is total, a tailored plan for transitioning to restored oil ought to be established, thinking about aspects such as compatibility with existing materials and functional problems. Educating for upkeep workers is essential, as they must comprehend the distinct residential or commercial properties of regenerated oils and how to manage their application properly.

Carrying out a rigorous surveillance program will promote the assessment of efficiency metrics post-implementation, ensuring the restored oil meets the needed functional criteria. Transformer Oil Regeneration Plant. Additionally, developing a normal maintenance routine will certainly help in recognizing potential problems early and permit prompt restorative activities

Conclusion

Finally, the fostering of regenerated oil for transformer maintenance provides a viable service that lines up financial advantages with environmental sustainability. By decreasing expenses connected with oil adjustments and waste disposal, while concurrently extending the life expectancy of devices, companies can boost functional efficiency. The transition to regenerated oil not only reduces environmental effects however additionally sustains more comprehensive sustainability goals, making it a sensible option for contemporary upkeep methods in the power market.

Regrowed oil, usually referred to as re-refined oil, is a Full Article critical component in the maintenance of transformers, providing both environmental and economic advantages. This oil is acquired from made use of mineral oils that have gone through a detailed filtration process, efficiently eliminating contaminants and restoring the oil to a quality similar to virgin oil.Additionally, taking on regrowed oil not only sustains cost-efficient upkeep approaches however also decreases the requirement for new oil manufacturing, consequently preserving all-natural resources. One of the primary advantages is the reduction of waste oil disposal, as regenerated oil is derived from the recycling of made use of transformer oil, dramatically reducing the volume of hazardous waste created. Regrowed oil, produced via sophisticated purification procedures, provides comparable performance to new oil at a portion of the cost.

Report this page